Nutrition & Food Chemistry

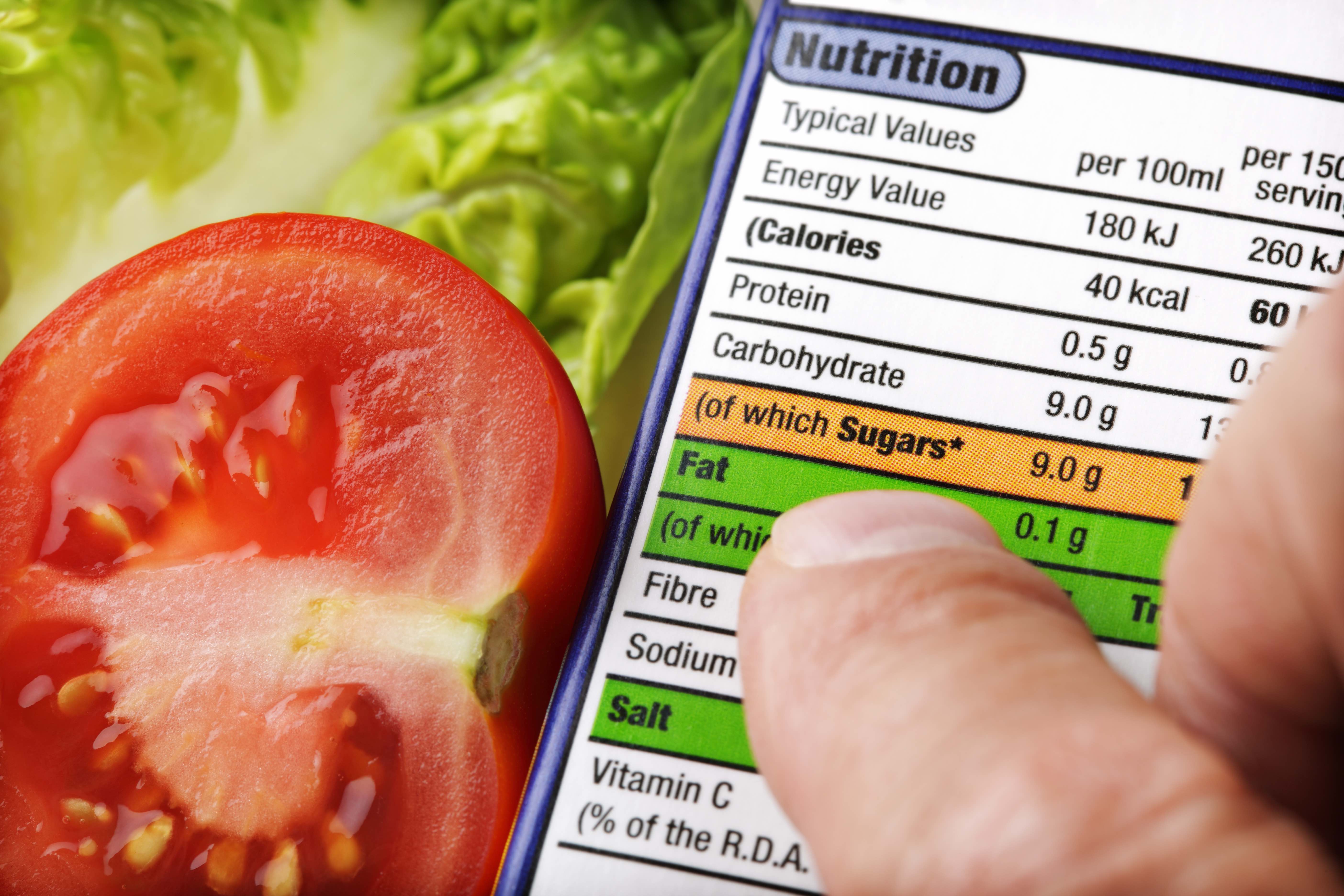

Premier Analytical’s Comprehensive Nutrition Service ensures accurate “on pack” information for your consumer.

Premier Analytical Services is one of the leading food testing centres in Europe, can supply you with a service that is designed to provide comprehensive support in this area delivering the highest value for money by offering:

- Consultancy advice

- Comprehensive scope of UKAS accredited analyses

- Fast, reliable results and interpretation.

You can rely on our advice and analytical results to provide accurate information for your consumers.

You can be confident that as one of our customers we will help you to implement the most appropriate testing regime.

You can use our service to monitor your products with regard to any Nutrition Claims that are made.

The Comprehensive Nutrition Service from Premier Analytical Services provides information on which you and your consumers can rely.

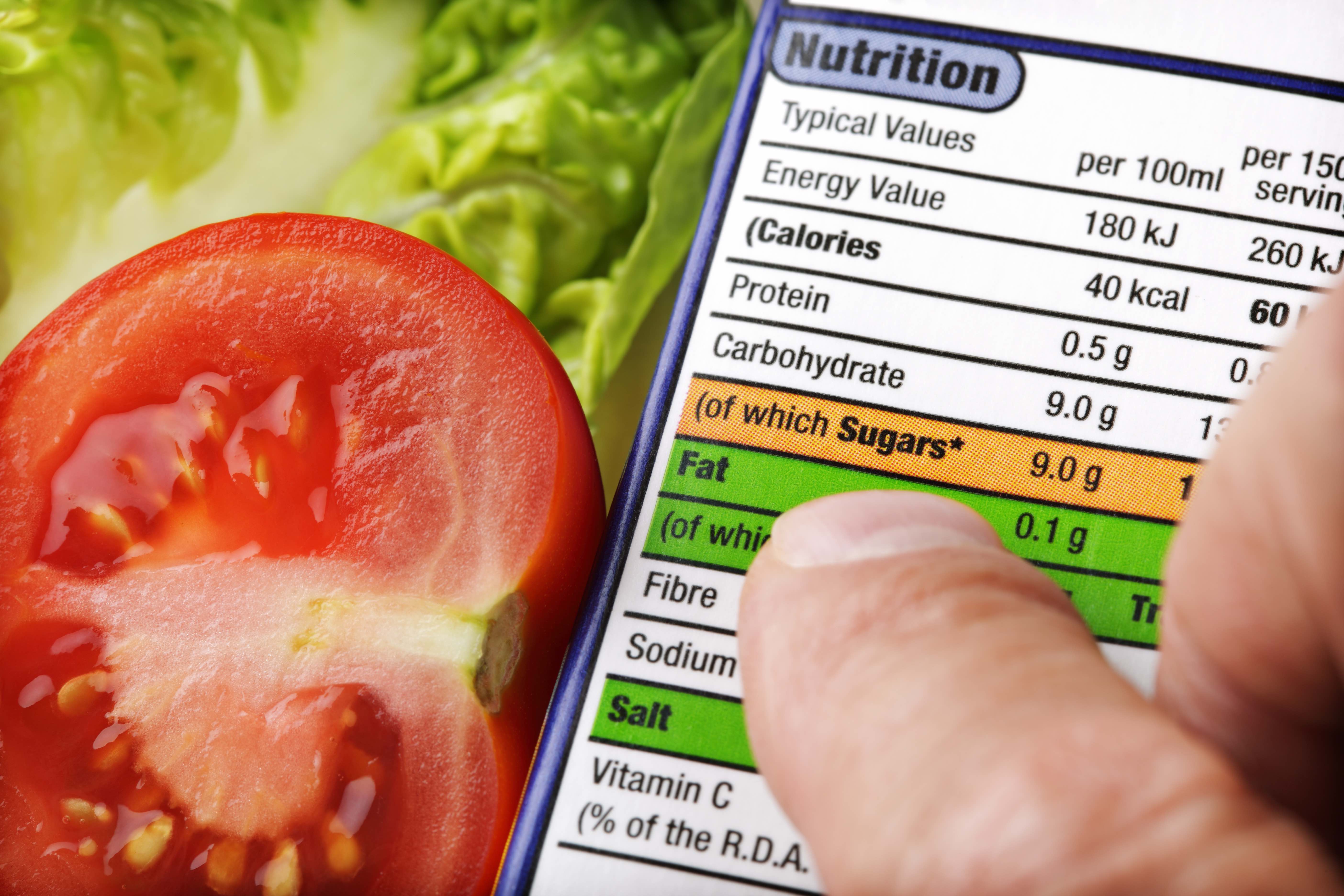

Mandatory Nutrition Labelling

Information must be declared per 100g 0r 100ml of the food. Or per portion, with the number of portions in a pack listed.

Consultancy & Advice

This new Regulation also changes the format that must be used for nutrition labelling of foods in the EU – all foods produced from 13th December 2014 must comply with the new rules.

The rules for making nutrition or health claims on foods in the EU have also recently undergone major changes and continue to evolve.

Nutritional labelling is a complex area wherein the potential for error is very high. Premier Analytical Services’s consultants can help you to get it right first time with advice that will answer questions such as:

What nutrition labelling rules apply to your particular food product?

Do the claims you make on pack or in advertising fall within the scope of the Nutrition & Health Claims Regulation – how does this affect the nutrition declaration?

What should be included in the declaration and what format and layout should be used?

What do you do about nutrients not listed in the regulations or for which there are no conversion factors?

What are the different requirements for vitamins and minerals as well as PARNUT foods?

What is the correct and best way to derive the information for the declaration?

Information should be based on:

- Calculation from known or actual average values of the ingredients used OR

- Calculation from generally established and accepted data OR

- Analysis. The method of derivation preferred by the major manufacturers, retailers and food industry authorities.

Calculation

If this is your preferred approach the experts at Premier Analytical Services can carry out calculations on your behalf or assist you to select and perform the most appropriate calculation.

Analysis

At the heart of our service is the full range of tests required to derive all the information needed to make accurate nutrition declarations. All of our analyses in this area are accredited by UKAS to the ISO 17025 standard. As such you can rely on the results and be confident that the declarations you are making on your products are a true representation that can in turn be relied upon by your consumers.

Interpretation

What the numbers mean and advice on any course of action that may be required – providing you with a Comprehensive Nutrition Service.

Premier Analytical’s Comprehensive Nutrition Service ensures accurate “on pack” information for your consumer.

Premier Analytical Services is one of the leading food testing centres in Europe, can supply you with a service that is designed to provide comprehensive support in this area delivering the highest value for money by offering:

- Consultancy advice

- Comprehensive scope of UKAS accredited analyses

- Fast, reliable results and interpretation.

You can rely on our advice and analytical results to provide accurate information for your consumers.

You can be confident that as one of our customers we will help you to implement the most appropriate testing regime.

You can use our service to monitor your products with regard to any Nutrition Claims that are made.

The Comprehensive Nutrition Service from Premier Analytical Services provides information on which you and your consumers can rely.

Mandatory Nutrition Labelling

Information must be declared per 100g 0r 100ml of the food. Or per portion, with the number of portions in a pack listed.

Consultancy & Advice

This new Regulation also changes the format that must be used for nutrition labelling of foods in the EU – all foods produced from 13th December 2014 must comply with the new rules.

The rules for making nutrition or health claims on foods in the EU have also recently undergone major changes and continue to evolve.

Nutritional labelling is a complex area wherein the potential for error is very high. Premier Analytical Services’s consultants can help you to get it right first time with advice that will answer questions such as:

What nutrition labelling rules apply to your particular food product?

Do the claims you make on pack or in advertising fall within the scope of the Nutrition & Health Claims Regulation – how does this affect the nutrition declaration?

What should be included in the declaration and what format and layout should be used?

What do you do about nutrients not listed in the regulations or for which there are no conversion factors?

What are the different requirements for vitamins and minerals as well as PARNUT foods?

What is the correct and best way to derive the information for the declaration?

Information should be based on:

- Calculation from known or actual average values of the ingredients used OR

- Calculation from generally established and accepted data OR

- Analysis. The method of derivation preferred by the major manufacturers, retailers and food industry authorities.

Calculation

If this is your preferred approach the experts at Premier Analytical Services can carry out calculations on your behalf or assist you to select and perform the most appropriate calculation.

Analysis

At the heart of our service is the full range of tests required to derive all the information needed to make accurate nutrition declarations. All of our analyses in this area are accredited by UKAS to the ISO 17025 standard. As such you can rely on the results and be confident that the declarations you are making on your products are a true representation that can in turn be relied upon by your consumers.

Interpretation

What the numbers mean and advice on any course of action that may be required – providing you with a Comprehensive Nutrition Service.